Wheel hub selection and misunderstandings: the bigger the better? If the width is not enough, use flanges?

release time:

2024-11-27

Tires are round and black. Wheels are round too, but not always black. In this article we will show you how to find the right wheels for your needs and vehicle model. Let's start with some of the markings on the wheels.

Tires are round and black. Wheels are round too, but not always black. In this article we will show you how to find the right wheels for your needs and vehicle model. Let's start with some of the markings on the wheels.

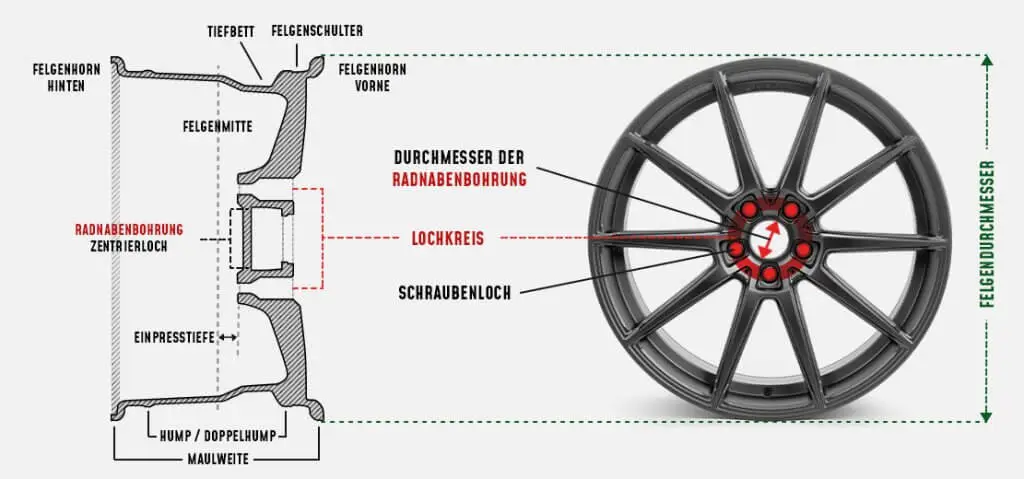

Let's look at an example: 8.5 J x 18 H2 ET 29 LK 5x120 MZ 57

These letters and numbers provide information about the wheel's construction, size and quality.

Here's what the numbers mean:

•8.5: The width of the wheel in inches, also called the flat face width. This width must be coordinated with the tire used. Because if you put a tire on a wheel that is too wide or too narrow, the tire will not become wider or better. If it is too wide, the shoulder of the tire cannot deform elastically, which reduces the vehicle's grip and comfort. So always stick to the recommended width or consult the tire manufacturer to determine the best width.

•J: The contour feature of the wheel edge.

•x: The wheel construction mark, here is a deep-bottom wheel. The purpose of a deep-bottom wheel is to allow the tire to be installed. The rim of the tire can only be moved from the other side to the top when the rim of the tire moves into the deep bottom.

•18: The diameter of the wheel hub in inches.

•H2: The structure of the wheel hub bed (here it is a double flange structure). The flange is a small "bump" on which the edge of the wheel rim makes a sound when inflating. Together with the air pressure, it maintains the stability of the tire. It is worth noting that there is a maximum inflation pressure when installing the tire. If this inflation pressure is exceeded, there is a risk of damage to the tire.

•ET 29: The offset of the wheel hub in millimeters.

•LK 5x120: The diameter and shape of the bolt holes in the wheel hub (here, 5 bolt holes with a hole diameter of 120 mm).

•MZ stands for the center ring with a diameter of 57 mm. This is the diameter of the hole used for centering the wheel hub.

•The following points are also important: the shape of the screws, that is, whether a spherical or conical bottom nut is used, as well as the angle of the conical bottom and the hole diameter. The length of the screws also varies from wheel to wheel.

Criteria for choosing wheels

The wheels also have to look good, so much so that some people call them "bikinis for brakes". However, for those who also value the vehicle's driving dynamics and comfort, just looking good is not enough. So, which parameters are equally important?

• Material: You can choose between steel, aluminum, magnesium or carbon fiber. It's a pure question of price. Many years ago, Mattig had great success with its culturally significant Mattig steel sports wheels.

Nowadays, car owners who pay attention to the appearance of their vehicles also use aluminum alloy wheels with winter tires in the European winter. These wheels are usually optimized for winter and are therefore slightly rougher than standard light alloy wheels, so that you don't cut your fingers when cleaning. They have a higher durability of impact, vibration and anti-scratch coating than standard light alloy wheels, so they also have better corrosion protection.

Magnesium is popular in racing because it is lighter than aluminum, but it is not completely suitable for everyday use. Magnesium ages and becomes brittle, and salt on winter roads accelerates this process. Wheels made of this material are also very expensive.

Carbon fiber is also occasionally used as a wheel material. But the biggest problem is that carbon fiber is a material with poor thermal conductivity, so it can only provide little cooling for the brakes by dissipating heat through the wheel strips. In addition, the fracture properties of carbon fiber are digital - either it breaks or it doesn't break. Therefore, if a carbon fiber wheel is damaged, the vehicle is suddenly in danger. But for other materials, the damage to the wheel may only cause bending instead of direct breaking, and you can still slide or continue to drive conditionally. Therefore, we usually choose aluminum materials to make wheels for daily use.

• Manufacturing process of aluminum wheels: Forged aluminum alloy wheels can be lighter than cast wheels due to their higher material strength.

Wheel structure

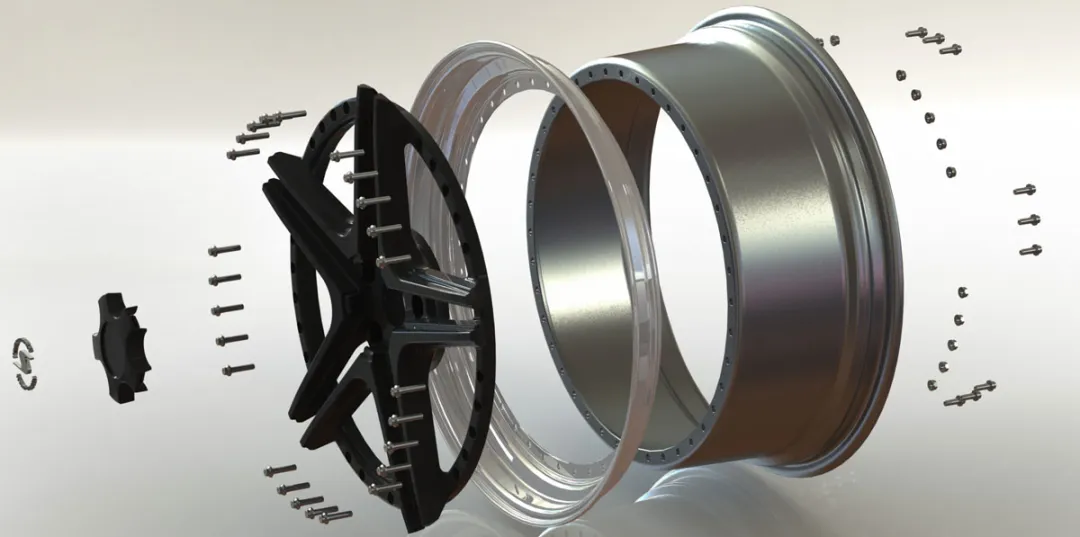

The structure of the wheel can be single or multi-piece: a single aluminum alloy wheel is made of a whole piece of metal, while a multi-piece wheel consists of a hub and a wheel disc, which are finally connected by bolts or welding. One advantage of this design is that the manufacturing of a single-piece wheel is simpler, and when the wheel is damaged, if it is a bolted multi-piece wheel, sometimes it is not necessary to buy a whole new wheel, and the engineer also has more design options. In some racing projects, the process of installing the tire can be simplified by disassembling the multi-piece wheel.

Choice of wheel size

The choice of size is usually not only based on technical factors, but may also be limited by the rules of the sport we are engaged in or the availability of the required tires. Not every size is suitable for our favorite car. We can observe a phenomenon that the wheel diameter of the mass-produced cars around us is always getting bigger and bigger. Because we want more comfort. This makes the car heavier, and with it comes bigger brakes. Therefore, we now need larger wheels. Since the modification industry likes to exaggerate everything, there are naturally some excessive modifications in wheel size, such as the size of car wheels can be increased to 23 inches. From the perspective of driving dynamics, this certainly doesn't make much sense, because we will increase the drag torque during acceleration. In addition, the oversized wheel makes the shoulder of the tire almost disappear. Although the deformation of the sidewall will be smaller, the extremely thin sidewall will also lead to the loss of comfort and handling. Therefore, the smallest possible wheel that can be stuffed into the brake system may be the best choice. However, there may be difficulties in tire selection. So this is another choice in car design that you can't have your cake and eat it too. At present, 18-inch wheels are very common in motor sports. For example, F1 has changed from 13-inch wheels to 18 inches. Because tire manufacturers have also done a lot of research and development work on this size, the results of racing can be better applied to the field of civilian cars.

The mouth width or wheel width of the wheel

As with the diameter, the first thing we need to pay attention to is the space issue, especially for the front axle, which is also responsible for steering. There are also legal issues. The law stipulates that the running surface of the tire must be half covered from above. Therefore, either the fender needs to be widened or the wheel needs to be adjusted to the inside of the standard fender.

Wheel offset

We cannot move the new wheel inwards or outwards at will, because the wheel offset must take into account several factors. As we learned in the article on the tire grinding radius, the tire grinding radius should be slightly negative and should only be a few millimeters. This means that we cannot deviate from the original wheel offset at will. The recommendation is to reduce the standard wheel offset, which is usually based on a small negative steering radius, by up to 10 millimeters. This will minimize the vehicle's sensitivity to lanes or uneven roads while keeping the vehicle's dynamic performance within reasonable limits. If the correct wheel offset is not available, it is also possible to use a flange to return to a technically reasonable ET value. Therefore, we need a slightly larger ET wheel and use it with a flange to adjust it to the correct size. The flange has a gradient of several millimeters. However, the use of flanges is not always without problems, since it doubles the tolerances of the hub center and the contact surface, which can cause vibrations and uneven running of the wheel. In addition, the screws or bolts become longer, which means that the screws are stretched more. Therefore, always use high-quality flanges and screws and pay attention to the fact that the screws have enough threads to ensure that they are stable.

Weight and stability

If you do a little research in online forums, you will often see that people want a wheel that is as light as possible. But few people can explain why lightweight wheels are good for vehicle dynamics and comfort. In addition, one often sees the term "unsprung mass". Lightweight wheels can move faster due to their lower inertia and therefore provide more grip. Because the wheel can follow the bumps of the road faster and more accurately. In addition, after the shock absorbers and springs, the wheel reacts less to ground waves, which improves the comfort of the vehicle. In addition, a stable wheel is likely to be more durable in the extreme conditions of racing sports. Therefore, the wheel should be as light and stable as possible.

Keywords:

Previous:

Recommended News

Contact Us

Tel: 0086-59586155888 EXT555

E-mail: slkwheel@slkwheel.com

Add: High Technology Park In Luncang,Nanan City,Fujian Province ,China

Follow Us

WEB